White Label vs. Private Label Pharmaceutical - What's the Difference?

White label manufacturing offers a turnkey solution for creating a branded line of pharmaceutical products, while private label manufacturing involves a higher level of customisation and collaboration for the final product.

If you're looking to work with a pharmaceutical manufacturer, here's what you need to know about the differences between white label vs private label.

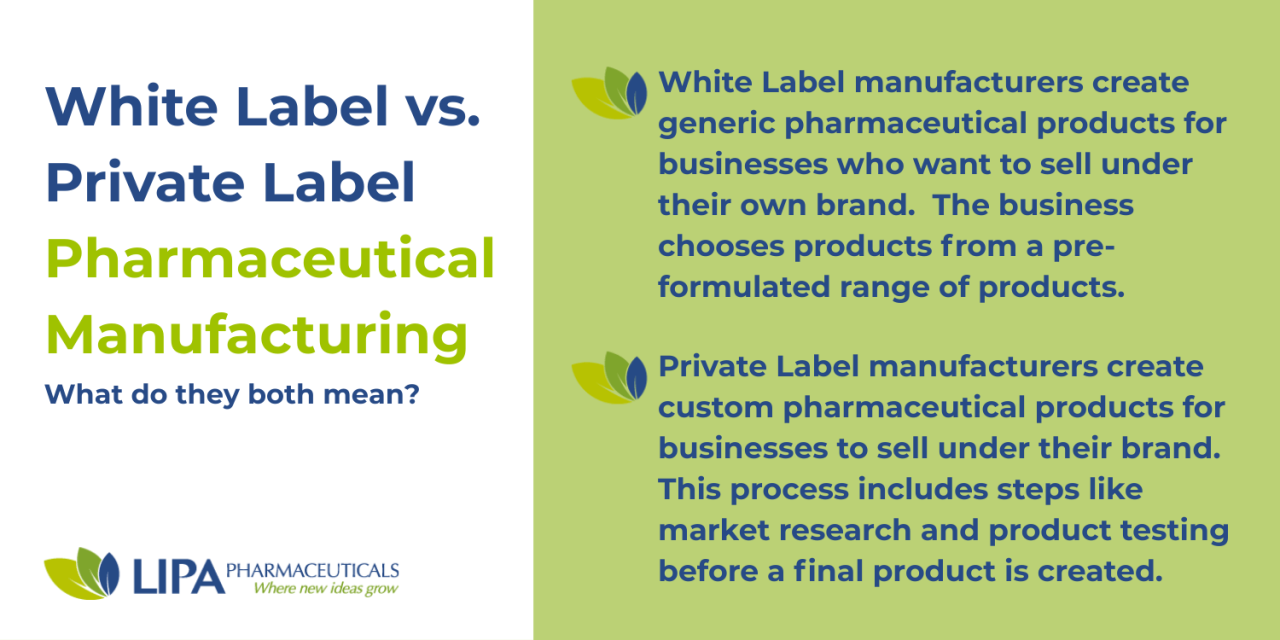

What Is White Label Pharmaceutical Manufacturing?

White label manufacturing is the process of creating generic pharmaceutical products that are sold to businesses that want to sell products under the brand. White label pharmaceutical manufacturing can include rebranding the product according to the business's brands, visuals, and messaging.

Under a white label arrangement, businesses are provided with a range of pre-formulated products to choose from that have been created by the manufacturer. Businesses submit an order for the volume and type of product, and the white label manufacturer produces the order.

What Is Private Label Pharmaceutical Manufacturing?

Private label manufacturing is the process of creating custom pharmaceutical products that the business can sell under the brand. Private label will include conducting market research, creating and testing product formulations, and production of the finalised product. Private label manufacturing can also include complementary packaging and labelling services to register the new product with the local market's authority for pharmaceutical products.

White Label vs. Private Label For Pharmaceutical Products

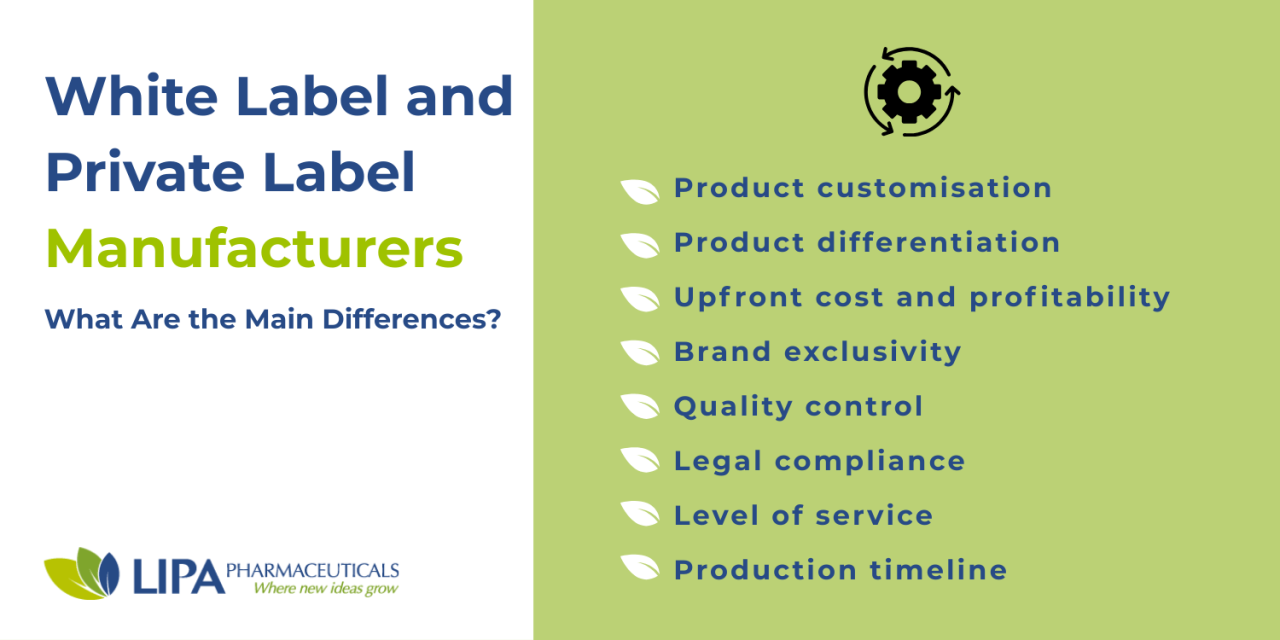

Product customisation

The clear difference between white label and private label manufacturing is the type of product that businesses can procure and sell.

Private label services are suitable for businesses that want more control over the product. Businesses can decide every aspect of the product, from the inclusion of specific ingredients to delivery formats and colour.

White label products are pre-formulated by the manufacturer. Businesses can customise the product packaging in line with the brand.

Product differentiation

One of the biggest benefits of opting for private label manufacturing is the opportunity to create a truly unique product that can stand out in the market. According to a 2011 audit by the Australian National Audit Office, there were over 10,000 complementary medicines on the Australian market - and the number is likely to have increased since then.

White label products are pre-formulated and tend to be more generic, making it more difficult for white label products to stand out in the market. Private label products can be created with exclusive or novel ingredients that boost market appeal.

Upfront cost and profitability

Private label manufacturing generally has higher upfront costs compared to white label services. Private label services also tend to have large minimum order quantities, raising the cost of pharmaceutical manufacturing.

Private label products generally make more profit and provide better long-term returns compared to white label products. Private label products can be tailored to specific markets, which helps improve sales. According to a report from Oracle Retail, private label products can earn 25-30% higher profit margins than branded products.

Brand exclusivity

Private label products are exclusive to the client. The formula, packaging, and design are not shared with other companies, protecting the brand's market position.

White label products are sold to multiple businesses. Different product brands can have the same formula, resulting in higher competition between similar products.

Quality control

White label products require less testing to meet an acceptable level of quality, potentially resulting in a lower standard of quality control than what clients expect, opening the door to unexpected complications.

Private label products involve more testing during development. Manufacturers check the formula for safety, stability, and compliance, allowing for a higher level of oversight before the product reaches the market.

Legal compliance

White label products have already obtained the necessary certification and labelling requirements from a governing authority like the Therapeutic Goods Administration (TGA) in Australia. White label services allow businesses to skip the complicated process of applying to get the pharmaceutical product approved before it can be sold on the market.

Private label products must undergo the registration and labelling process - most private label manufacturers offer support for the application process to get the product approved on behalf of businesses.

Level of service

White label manufacturers offer a turnkey solution for businesses - the level of service is transactional. Manufacturers supply a ready-made product for branding and distribution.

Private label manufacturing involves more collaboration. Manufacturers may assist with updating formulas, going to market, and compliance as part of an ongoing working relationship.

Production timeline

White label manufacturing can have short lead times, as pre-formulated products have been refined by the manufacturer.

Private label manufacturing can have a longer timeline that includes sourcing ingredients, refining product formula, and necessary testing. Businesses should contact manufacturers early to account for a longer time to market.

Choosing Between White Label and Private Label

The choice between the two types of pharmaceutical manufacturing will come down to your business's goals for the product. Private label manufacturing can create a unique product to meet specific market demands, while white label services provide a faster time to market.

Lipa Pharmaceuticals is Australia's leading contract manufacturer for complementary medicines. We provide both white label and private label pharmaceutical manufacturing services for vitamins, sports supplements, and probiotics across a range of delivery formats. We have a full-service process that includes in-house formulation, testing, and packaging for our private label clients. Get in touch with our team to find out how we can help you create a custom pharmaceutical product for your brand.

Related Posts

By accepting you will be accessing a service provided by a third-party external to https://www.lipa.com.au/