How Long to Manufacture Private Label Supplements?

Private label manufacturing is a multifaceted process that involves material sourcing, research and development, testing, production, packaging, and dispatch of product. Generally, the private label manufacturing process can take 18 weeks from the submission of a purchase order to the dispatch of the products, depending on material availability and packaging sourcing.

For businesses looking to create a custom private label supplement product, understanding the general timeline can clarify when to expect test samples and when the final product can be shipped.

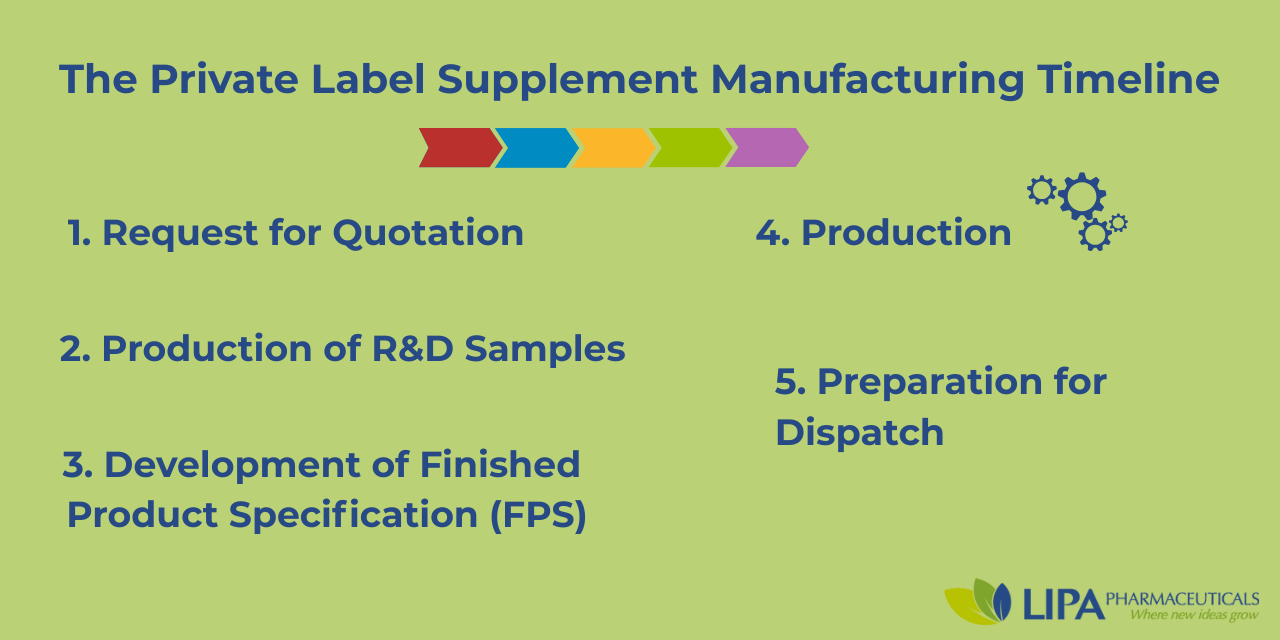

The Private Label Supplement Manufacturing Timeline

1. Request for Quotation

The process of private label supplement manufacturing begins when businesses send a request for quotation (RFQ) to the supplement manufacturer. The RFQ details the production requirements of the business, including:

• Type of supplement (dietary, sports, health)

• Supplement delivery form (hard or soft capsule, tablet, liquid, creams & gels)

• Packaging requirements (Glass bottles, Blister packaging, HDPE packaging)

• Desired order quantity

• Labelling and compliance requirements (AUST L or AUST R)

Once the RFQ is submitted, the manufacturer will contact clients to gather any missing or additional information for the supplement product. Refining the RFQ typically takes 5 to 20 business days, after which the manufacturer will provide a tailored quote.

2. Production of R&D Samples

The supplement manufacturer will begin research and development to create the supplement samples based on formulation. The research and development team assesses the raw materials for compliance with TGA requirements - all raw materials used for supplement manufacturing in Australia must either be on the list of TGA-approved materials or submitted for testing to be registered as a new ingredient.

The research and development team conducts rigorous testing through bench trials to refine the supplement product's formula for efficacy and stability. Results of the bench trials are also used to identify issues with the formulation. Prototype samples are produced and presented to the client for review.

The entire testing and production timeline for R&D samples can take 20 business days from the approval of the quote. Additional testing requirements will extend this timeline - for example, the Preservative Efficacy Test (PET) for liquids will add approximately 5 weeks to the timeline.

3. Development of Finished Product Specification (FPS)

Once business clients have provided approval for the R&D samples, the supplement manufacturer will move on to the next stage: Finished Product Specification (FPS) development.

The supplement manufacturer finalises the formula of the supplement product in the FPS. The FPS serves as a blueprint for large-scale production as well as a requirement for listing or registering the supplement product on the Australian Register of Therapeutic Goods (ARTG). The classification of the supplement product will determine its regulatory requirements for manufacturing and labelling - lower risk medicines are listed on the ARTG, while higher risk medicines must be registered on the ARTG.

The development of the Finished Product Specification will take about 15 business days from the approval of the R&D sample product.

4. Production

Production is the next stage of the manufacturing process - this is where the custom supplement product is produced at scale using the FPS as a guide.

The production stage can take between 20-30 business days, depending on the size of the purchase order and availability of raw materials. Larger purchase orders will require more time for production. In some cases, the manufacturer may need more time to source raw materials due to low availability or register a new material with the TGA.

5. Preparation for Dispatch

Full service supplement manufacturers offer packaging services for the produced supplement products. Before dispatching the order to the business client, the supplement is packaged in the desired form with the appropriate branding and labelling.

Most supplement manufacturers have a customer service representative to handle the regulatory approval of the product's packaging label. The label approval process involves the addition of the product's AUST L or AUST R labelling, the name of the product, branding colours and graphics, ingredient information, and health claims.

Label approval is generally obtained two months before the requested dispatch date.

Estimated Lead Time for Private Label Supplement Manufacturing

Most orders have a lead time of approximately 18 weeks, starting from the placement of a purchase order with the manufacturer to the dispatch of finished products. This lead time can be reduced to 16 weeks for subsequent orders of the same supplement product, as the sample production and FPS development will no longer be necessary. Lead times will mainly be affected by the availability of raw materials and the complexity of the product formulation.

Lipa Pharmaceuticals is Australia's leading private label supplement manufacturer for sports, health, and beauty supplements. As the eight-time winner of Complementary Medicines Australia's 'High Quality Manufacturer' award, our capability to manufacture high quality pharmaceuticals products is supported by an in-house research team of specialists and a GMP-certified production facilities. Work with us to create custom formulated products for your brand - get in touch with us by submitting a request for quotation form.

Related Posts

By accepting you will be accessing a service provided by a third-party external to https://www.lipa.com.au/